Your cart is empty

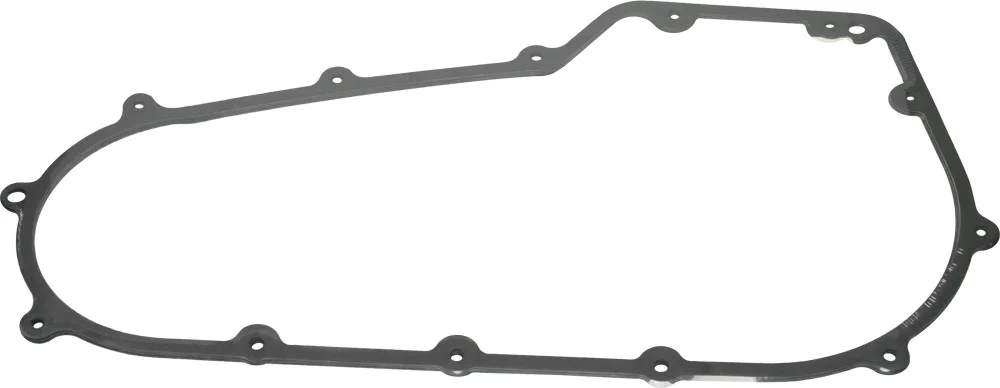

Start ShoppingCOMETIC C9145F5 Evo Big Twin/Twin Cam Primary Housing Gasket - EST AFM Gasket for Reliable Sealing

Description

Ensure flawless engine performance with Cometic's C9145F5 EST primary housing gasket, engineered for big twin and twin cam engines. This advanced gasket delivers unmatched sealing reliability while simplifying maintenance with its reusable design and no-sealant construction.

Key Features

- EST Extreme Sealing Technology: Advanced sealing system reduces leaks and ensures long-term durability in high-performance engines.

- AFM Aluminum Foam Material: Chemically blown nitrile rubber bonded to an aluminum core provides superior heat resistance and compression resilience.

- Reusable Design: Maintains torque retention and can be reused if undamaged, reducing long-term maintenance costs.

- No Additional Sealants Required: Eliminates the need for extra sealants, saving time and ensuring consistent sealing performance.

- Primary Housing Compatibility: Precision-engineered for primary covers on big twin and twin cam engines, including Harley-Davidson models.

Why Choose This Product

Cometic's C9145F5 gasket combines cutting-edge material science with rugged construction to deliver exceptional sealing reliability. The AFM material withstands extreme temperatures and compression, while the EST technology ensures minimal leakage even under heavy engine loads. Its reusable design saves money and labor, making it a cost-effective solution for riders who demand both performance and durability. Manufactured in the USA, this gasket meets the highest standards for quality and precision, giving riders peace of mind with every ride.Log in to submit a price match request.

Ensure flawless engine performance with Cometic's C9145F5 EST primary housing gasket, engineered for big twin and twin cam engines. This advanced gasket delivers unmatched sealing reliability while simplifying maintenance with its reusable design and no-sealant construction.

Key Features

- EST Extreme Sealing Technology: Advanced sealing system reduces leaks and ensures long-term durability in high-performance engines.

- AFM Aluminum Foam Material: Chemically blown nitrile rubber bonded to an aluminum core provides superior heat resistance and compression resilience.

- Reusable Design: Maintains torque retention and can be reused if undamaged, reducing long-term maintenance costs.

- No Additional Sealants Required: Eliminates the need for extra sealants, saving time and ensuring consistent sealing performance.

- Primary Housing Compatibility: Precision-engineered for primary covers on big twin and twin cam engines, including Harley-Davidson models.

Why Choose This Product

Cometic's C9145F5 gasket combines cutting-edge material science with rugged construction to deliver exceptional sealing reliability. The AFM material withstands extreme temperatures and compression, while the EST technology ensures minimal leakage even under heavy engine loads. Its reusable design saves money and labor, making it a cost-effective solution for riders who demand both performance and durability. Manufactured in the USA, this gasket meets the highest standards for quality and precision, giving riders peace of mind with every ride.| SKU | GM3AF7BC66 |

|---|---|

| MPN | C9145F5 |

| Brand | Cometic |

| Category | Gaskets/Seals |

Log in to write a review.

Reviews

No reviews yet. Be the first to review this product!

Frequently Asked Questions

No. The AFM/EST Cometic primary gaskets are engineered to seal dry on clean surfaces. Follow the Harley‑Davidson torque specs in the service manual; additional sealant is generally not recommended unless the OEM procedure for your engine family specifically calls for it.

AFM/EST Cometic gaskets are designed to maintain torque retention and can sometimes be reused if they were not over‑compressed, torn, or contaminated. However, for best reliability and to avoid labor‑intensive rework, most technicians treat primary housing gaskets as single‑use parts, especially on customer or high‑mile bikes.

Yes. Cometic’s AFM material with an aluminum core typically offers better torque retention and resistance to heat and fluids compared with many OEM fiber gaskets. It is specifically designed to seal imperfect surfaces and resist long‑term compression set.

No. It is normally sold as a single primary housing gasket only. Derby cover gaskets, inspection cover gaskets, and drain plug O‑rings are usually sold separately or in complete primary gasket kits.

Use the torque values and sequence from the Harley‑Davidson service manual for your exact model and year. The gasket is designed to work with standard OEM torque specs; do not exceed those values to ‘make it seal’.

Installation Guide

Tools Required

- Harley service manual for your exact model

- Standard SAE socket set

- Allen/hex key set (primary cover screws)

- Torque wrench (inch-lb and ft-lb range depending on model)

- Plastic scraper or gasket scraper (non-metallic preferred)

- Brake cleaner or gasket surface cleaner

- Shop rags

- Drain pan (for primary fluid)

- Primary fluid / transmission jack or stand (as applicable)

Pro Tips

- Lay the new gasket dry on clean, oil‑free surfaces; align all bolt holes before installing the cover

- Snug bolts by hand in a crisscross pattern, then torque in stages to the OEM spec from the factory service manual

- Inspect the primary cover and case sealing surfaces for nicks or scratches; lightly dress with a fine file or Scotch‑Brite if needed

- Replace the primary drain plug O‑ring and derby/inspection cover gaskets at the same time to avoid chasing new leaks

- After the first ride, inspect for weeps around the perimeter of the primary cover and re‑check torque if your manual allows

Common Mistakes to Avoid

- Using RTV or additional sealant on the AFM gasket (Cometic designs these to be installed dry unless otherwise specified by OEM manual)

- Re-using old, crushed primary cover screws or washers that can affect clamping load

- Not fully cleaning old gasket material from both mating surfaces before install

- Over-tightening or unevenly tightening primary cover bolts, leading to warping or leaks

- Skipping primary fluid level check and refill after reinstalling the cover

Comparison vs Stock/OEM

Cometic’s AFM/EST primary housing gasket is engineered to outperform typical OEM fiber or paper gaskets by providing better torque retention, improved sealing on less‑than‑perfect surfaces, and superior resistance to oil and heat.

Improvements

- Aluminum core resists blow‑out and maintains structure during repeated heat cycles.

- Chemically blown nitrile rubber sealing layer conforms to micro‑imperfections on sealing surfaces.

- Generally less prone to seepage over time compared with many OEM gaskets.

- Often capable of multiple removals/installs if handled carefully (unlike many paper gaskets).

Considerations

- Initial cost can be slightly higher than basic OEM gaskets.

- Best performance is achieved only when both mating surfaces are properly cleaned and bolts are torqued to spec.

- Some technicians still prefer single‑use practice for maximum reliability despite AFM’s reusability claims.

Durability & Warranty

What Others Are Saying

Reviews from across the web